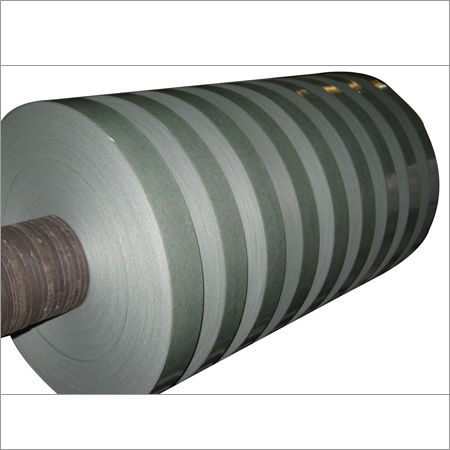

Insulation Fish Paper

Insulation Fish Paper Specification

- Width

- 10 mm 1250 mm

- Elongation

- 2% 4%

- Thermal Conductivity

- 0.23 W/mK

- Thickness

- 0.13 mm 0.45 mm

- Length

- Variable (customized as per requirement; typically 50 m or 100 m per roll)

- Shelf Life

- 12 months

- Density

- 1.3 Gram per cubic centimeter(g/cm3)

- Product Type

- Insulation Paper

- Application

- Electrical insulation, slot liners in motors, transformers, and other electrical devices

- Material

- Insulating cellulose paper

- Rated Voltage

- 6 kV 10 kV

- Tensile Strength

- 60 N/10 mm 90 N/10 mm

- Function

- Thermal and electrical insulation

- Heat Resistance

- Class A (105C)

- Paper Core

- Yes

- Weight

- Customized, depends on width and length

Insulation Fish Paper Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Payment Terms

- Cheque

- Supply Ability

- 300000 Kilograms Per Month

- Delivery Time

- 7-10 Days

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Insulation Fish Paper

We are one of the prominent firms, involved in the business of manufacturing and supplying Insulation Fish Paper. This paper has good thermal, electric and mechanical properties. Our clients' can avail this paper in different thickness and sizes as per their requirement. It is well known in the market due to its excellent tear strength, enhanced durability, uniform thickness as well as supreme finish. Prior to final dispatch, it is checked on different standard parameters by our experts in order to deliver defect free range. It is often utilized with motor windings and for gasket insulation. In addition, Insulation Fish Paper is provided in safe packaging to avoid outer impacts during transit.

Versatile Electrical Insulation Solutions

Insulation Fish Paper offers reliable thermal and electrical insulation for a wide range of electrical devices, including motors and transformers. Its customizable width, thickness, and roll length make it suitable for various industrial and commercial requirements, ensuring optimal protection and efficiency wherever electrical insulation is critical.

High-Quality Material and Engineered Performance

Crafted from dense insulating cellulose paper with a density of 1.3 g/cm, this fish paper delivers superior tensile strength (60 N/10 mm 90 N/10 mm) and elongation, ensuring durability under demanding conditions. Its Class A heat resistance and rated voltage guarantee safety and performance in environments up to 105C and voltages up to 10 kV.

FAQs of Insulation Fish Paper:

Q: How is Insulation Fish Paper used in electrical equipment?

A: Insulation Fish Paper is primarily employed as slot liners, barriers, and wraps within motors, transformers, and various electrical devices. It helps isolate conductive components, providing essential electrical insulation and minimizing thermal risks to extend equipment life and improve operational safety.Q: What benefits does cellulose fish paper offer over other insulation materials?

A: This fish paper delivers excellent thermal and electrical insulation, Class A heat resistance (up to 105C), and sufficient mechanical strength. Its eco-friendly cellulose composition and customizable dimensions make it a preferred choice for reliable, safe, and sustainable insulation in electrical applications.Q: When should I replace Insulation Fish Paper in my devices?

A: It is recommended to replace fish paper during equipment overhauls or whenever visual inspection reveals signs of wear, breakdown, or loss of mechanical strength. Since it has a shelf life of 12 months, ensure regular inventory checks and use fresh stock for optimal performance.Q: Where can I source Insulation Fish Paper in India?

A: Insulation Fish Paper is available from multiple importers, manufacturers, suppliers, and traders across India. It can be obtained directly from electrical insulation product dealers, either as standard rolls or customized orders based on width, length, and thickness requirements.Q: What is the manufacturing process for Insulation Fish Paper?

A: The fish paper is manufactured by compacting insulating cellulose pulp into sheets, which are then processed to yield the required thickness, width, and mechanical specifications. Rolls are finished with paper cores for stability, and customized orders are cut as per application needs.Q: How do I determine the correct fish paper thickness for my application?

A: Select the thickness based on your devices voltage rating, space constraints, and required insulation strength. For instance, higher voltage applications or tighter spaces may require thicker or more robust fish paper, within the 0.13 mm to 0.45 mm range listed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fish Insulated Paper Category

Fish Insulating Paper

Minimum Order Quantity : 10 Tons

Function : Electrical insulation, heat resistance

Shelf Life : 12 months

Paper Core : Yes

Rated Voltage : Up to 1.2 kV

Product Type : Other, Insulating Paper / Fish Paper Roll

Insulation Fish Papers

Minimum Order Quantity : 10 Tons

Function : Dielectric and electrical insulation

Shelf Life : More than 5 years

Paper Core : Yes, standard core provided

Rated Voltage : 600 V to 900 V

Product Type : Other, Insulation Fish Paper

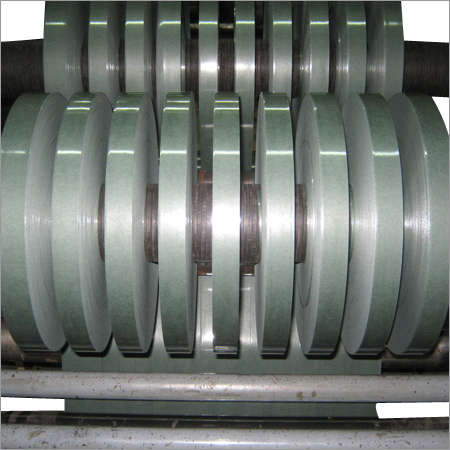

Slitted Insulation fish paper

Minimum Order Quantity : 10 Tons

Function : Provide electrical and thermal insulation

Shelf Life : Up to 24 months under proper storage conditions

Paper Core : Standard 3 or 76 mm ID core

Rated Voltage : up to 600 V

Product Type : Other, Slitted insulation fish paper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS