Insulating Paper Roll

Insulating Paper Roll Specification

- Width

- 950 Millimeter (mm)

- Thickness

- 0.2 Millimeter (mm)

- Elongation

- 2%

- Density

- 0.75 Gram per cubic centimeter(g/cm3)

- Shelf Life

- 24 Months

- Length

- 100 Meter (m)

- Thermal Conductivity

- 0.040 Watt/Meter/K (w/(m.k)

- Product Type

- Insulating Paper Roll

- Application

- Electrical insulation, transformer winding, cable wrapping

- Material

- Insulating cellulose paper

- Rated Voltage

- up to 35 Volt (V)

- Tensile Strength

- 80 N/10 Newtons per Millimetre Squared (N/mm2)

- Function

- Dielectric barrier, heat resistance

- Heat Resistance

- Class A (105C)

- Paper Core

- 38 mm inner diameter

- Weight

- 5 kg per roll Kilograms (kg)

Insulating Paper Roll Trade Information

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 300 Tons Per Month

- Delivery Time

- 7-10 Days

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

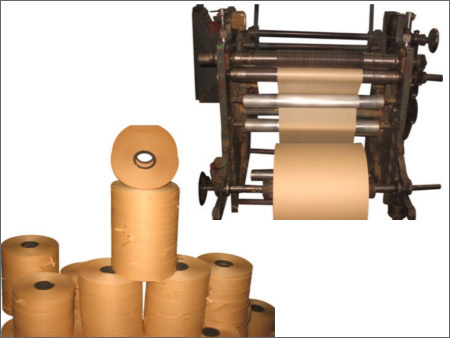

About Insulating Paper Roll

In order to cater to the diverse requirement of clients, we have been involved in manufacturing and supplying Insulating Paper Roll. It is widely used to insulate the windings of low voltage transformers and for winding wire as well as in the form of strips of paper insulation between winding layers. Prior to final dispatch, it is checked on different standard parameters by our experts to ensure its premium quality and superior finish. It is highly appreciated in the market due to its uniform thickness, enhanced durability, and lightweight. Apart from this, Insulating Paper Roll can be availed by our clients in different packaging options at affordable market prices.

Superior Electrical Insulation Performance

Manufactured from insulating cellulose paper, this roll guarantees reliable electrical insulation for transformer windings and cable wrapping. Its dielectric barrier function and high voltage rating of up to 35 kV assure protection and safety in critical environments. The papers consistent thickness and elongation support smooth application during installation.

Exceptional Heat Resistance and Durability

Engineered to withstand high temperatures up to Class A (105C), the insulating paper roll maintains its integrity even in challenging thermal settings. The tensile strength of 80 N/10mm and a shelf life of 24 months highlight its durability, ensuring dependable performance over extended periods.

Versatile Application and Convenient Handling

Ideal for a range of electrical insulation uses, this product comes in large rolls (950 mm width, 100 m length) with a paper core diameter of 38 mm for easy installation and unwinding. Lightweight at 5 kg per roll, it is accessible to manufacturers, importers, suppliers, and traders throughout India.

FAQs of Insulating Paper Roll:

Q: How does the insulating paper roll enhance electrical safety in transformer winding and cable wrapping?

A: The roll acts as a dielectric barrier, with a rated voltage of up to 35 kV, effectively insulating wires and windings to prevent electrical breakdown, short circuits, and accidents during operation.Q: What is the process for installing the insulating paper roll in electrical equipment?

A: To install, unroll the paper to the desired length and carefully wrap it around the transformer windings or electrical cables, ensuring complete coverage and smooth application for optimal insulation performance.Q: What benefits does the insulating cellulose paper provide compared to synthetic alternatives?

A: Insulating cellulose paper offers excellent dielectric properties, heat resistance up to 105C (Class A), and a sustainable, biodegradable solution with strong tensile strength and easy handling, making it suitable for a variety of electrical applications.Q: When should the insulating paper roll be replaced or inspected for optimal performance?

A: It is recommended to inspect the paper periodically and replace it if any signs of degradation, tears, or reduced dielectric performance are detected. Adhering to the 24-month shelf life ensures reliable insulation.Q: Where is the insulating paper roll primarily used within the electrical industry?

A: The product is mainly used for transformer winding insulation, cable wrapping, and as a dielectric barrier in other high-voltage electrical components found in manufacturing and utility environments.Q: How does the products heat resistance impact its usability in electrical systems?

A: With Class A heat resistance (up to 105C), the paper maintains its insulating properties in elevated temperature conditions, protecting electrical systems from thermal breakdown and enhancing longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Insulating Paper Category

Slitted Insulating Paper

Minimum Order Quantity : 10 Tons

Tensile Strength : 60 N/15mm

Application : Electrical insulation in transformers, motors, and capacitors

Rated Voltage : Up to 35kV

Function : Electrical insulation, isolation, and winding protection

Shelf Life : 2 years under recommended conditions

Electrical Insulation Paper Roll

Minimum Order Quantity : 10 Tons

Tensile Strength : >70 N/10mm

Application : Electrical insulation for transformers, motors, and electrical equipment

Rated Voltage : Up to 600V

Function : Electrical insulation, protection against short circuit

Shelf Life : 2 Years

Insulating Slitted Paper

Minimum Order Quantity : 10 Tons

Tensile Strength : 60 N/10mm

Application : Electrical insulation in transformers, motors, and other electrical equipment

Rated Voltage : Up to 600V

Function : Dielectric insulation, thermal barrier

Shelf Life : 12 months (stored in dry conditions)

Electrical Slitted Insulating Paper

Minimum Order Quantity : 10 Tons

Tensile Strength : 60 N/10mm

Application : Used for electrical insulation in transformers, motors, and other electrical equipment

Rated Voltage : Up to 35 kV

Function : Electrical insulation and mechanical protection

Shelf Life : 24 months

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS